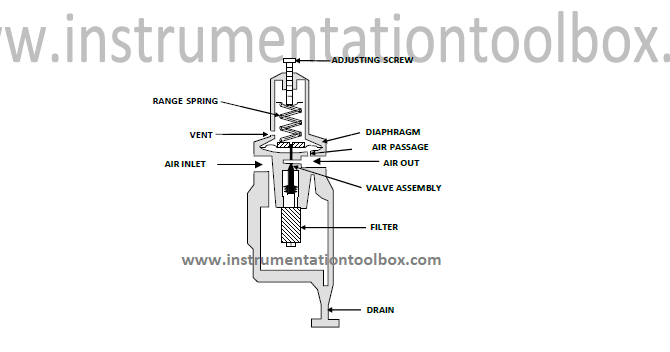

There is nothing complicated about the electronic air pressure regulator. It is basically used to reduce main plant equipment air supply to the proper pressure for air-operated equipment such as transmitters, control valves, etc. The Air inlet port provides the main air supply which is also responsible for regulations. The air compressor electronic pressure regulator is very important in controlling the pressure of the air flowing from the compressed air tank to the tool. The air pressure required for different air tools can be adjusted according to the application as all equipment may require different levels.

Does the Air Pressure Regulator Reduce the Flow?

Pressure regulating products are designed to control the amount of force generated by the fluid system. Electronic pressure control is commonly known as pressure regulators. And like the flow control Available in manual and electronic versions. The pressure regulator is not designed to control flow.

Different types of an electric air pressure regulator. It is used in many homes and industrial applications, such as controlling propane used in gas grills. To control oxygen in medical devices Industrial compressed air supply to control fuels in automotive engines and aerospace applications.

A flow Regulator Differs from a Pressure Regulator, so what’s the Dfference?

Pressure regulating valves generally involve regulating pressure upstream of a position by limiting the amount of liquid that is allowed to flow downstream. Flow control valves involve regulating the amount of liquid flowing through the bottom.

Do I need an Electronic air Pressure Regulator?

If you are in charge of a large compressed air system, you may have multiple digital pressure regulator that need to be checked between shifts. Multiple devices at the same time from the same compressor. You will need a controller for each pneumatic machine or pneumatic tool.

What is the Purpose of the air Pressure Regulator?

Electronic air pressure regulator is a simple device. It is used to reduce the main plant equipment air supply to the optimum pressure for air-operated equipment such as transmitters, control valves, etc.

What happens to the Air Regulator when the Compressed Air Stops?

The regulator gauge reading reflects the voltage drop across it. The same is true for compressed air in an air hose using an air tool/appliance. When the need for compressed air ceases, atmospheric pressure will begin to build. And pressure pulses can occur in the pipeline until the pressure rises beyond the original set point of control.

What type of Regulator is used in Pneumatic Tools?

Electronic air pressure regulator devices are used to regulate the pressure of various pneumatic tools. And they are usually available in both: a pressure reducing regulator allows adjustment from high to low pressure even in blind spot situations.

Precision Level Pressure Regulator Working

The standard grade regulator maintains a controlled pressure within two to five psi during normal operation as airflow requirements vary. Precision regulator maintains air pressure control valves to less than 0.5 psi variation. The precision regulator continuously expels a small amount of air to keep the flow valve open and operating. To know more about the working and use of digital regulators you need to get your hands on one!